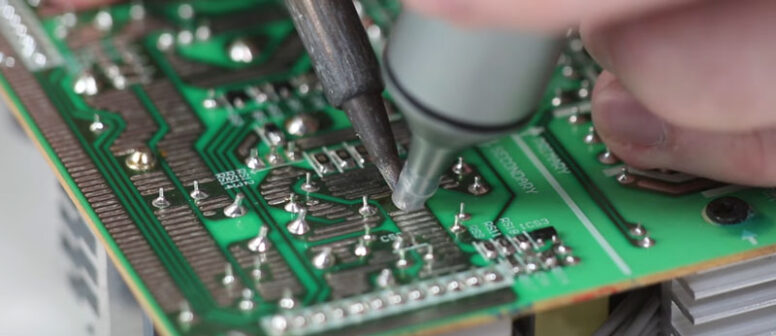

As you probably already know, soldering is the most important step in the assembly process of printed circuit boards. But, none of these processes are perfect, so, if you’ve made several errors along the way, you’ll have to utilize a desoldering pump in order to correct them – which can be a bit tricky if you’re a beginner.

If you’ve never used such a tool before, you might be wondering – what are the most common mistakes to avoid when using a desoldering pump? Luckily for all individuals that are wondering the same thing, the article below can help. But, before we take a look at the mistakes you should avoid, let’s learn what the device is:

Desoldering Pump: Explained

To put it simply, a desoldering pump is a tool that resembles a large pen. It is extremely useful for people that work on PCBs mostly because it allows them to easily and quickly remove any and all excess materials from the connections, without disturbing the other components. It’s most commonly used for fixing faulty connections since the users can remove them and then replace them with a new one relatively fast.

1. Not Priming And Activating The Device Before Use

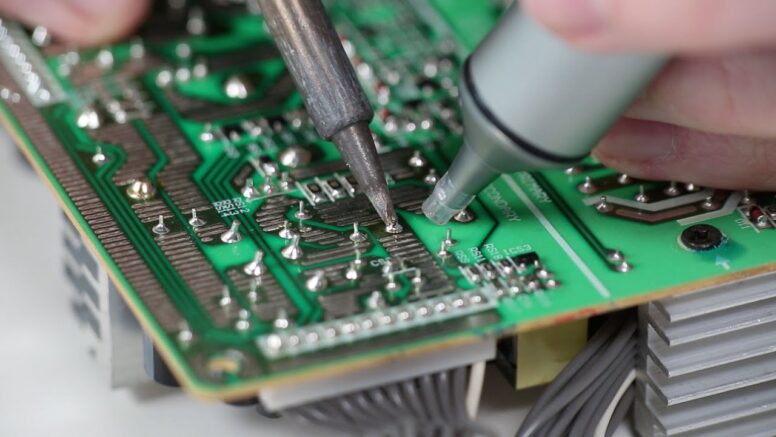

If you’ve just purchased your first desoldering pump, one of the first things that you’ll have to do is to prime and activate it several times before you actually use it. Why should you do this? Well, it’s quite simple – you must get used to the kickback the tool produces. If you don’t do this, you won’t be able to keep the nozzle steady, which implies that you might make more errors than you otherwise would.

To prime the device properly, you should tightly grasp it with one of your hands and press the plunger until you notice that it’s locked in its place. By doing this, you can ensure that the spring-loaded piston is ready for suctioning the materials from the printed circuit board. The activation process is quite simple, and it’s usually done by pressing the button on the tool. This releases the piston and creates suction.

2. Using The Tool on Small Mounted Components

Another common mistake that people make is utilizing the device near or on small surface-mounted parts (SMT, for short) of the printed circuit board. You should never use it on these components, mostly because it can cause heat spillover and once you try to suction it, you might end up dislodging the small components – something that is quite difficult to correct and you might end up needing a new PCB.

3. Not Cleaning And Maintaining The Device

Like all the other tools and equipment that you might use, you should never skip cleaning and maintaining your pump. If you don’t do this, it’ll probably stop working. It’s relatively easy to clean the tool and to begin, you’ll have to prime and activate it several times. This will push the rod through the device and it’ll also ensure that the material inside isn’t blocking it. Keep in mind, you might need to disassemble it to clean it, and if so, you should follow the user manual you received with the tool.

4. Not Understanding The Process

You might be surprised by the number of people who choose to use this particular device without understanding the entire process. When you’re a beginner, nothing will be easy, which is why you should ensure that you read some guides and watch some tutorials online in order to understand what you’ll have to do. If you want to see more information on how to use a desoldering pump, click here.

5. Trying to Remove Small Bits

There might be some small bits of solder that you want to remove, and if so, you should know that you shouldn’t do it, mostly because you might end up removing some important components from your PCB board. Instead of trying to suction those small bits, you should add more of it to the joint you’re working on. This will allow the material to stay in a liquid form for longer, and when it is a larger bit, it’ll be easier to remove it.

The Advantages of Using a Desoldering Device

Before we conclude this article, you should know that there are other methods for removing excess bits from the PCBs. However, they are more difficult to complete, which is why it’s always recommended that you use this device instead. The advantages of purchasing and using a desoldering pump are the following:

1. It’s Easier to Fix Things

One of the first advantages of using this tool is that it’ll allow you to easily and quickly fix faulty components on your printed circuit board, mostly because you can ensure that you don’t damage the smaller and larger parts. It’s also simpler to suction the excess material, instead of some other methods that you could use.

2. A Wide Range of Options

There is a wide range of options that you can find available on the market. For instance, these tools can come equipped with a heating gun, which means that you won’t have to use another tool for liquefying the connections. If you choose these options, you can save money since you won’t need to purchase an additional tool.

3. Quick And Efficient

No matter what device you opt for purchasing, the entire process will be quicker and more efficient, but more importantly, you’ll reduce the chances of making additional mistakes. And, you also won’t have to monitor where the solder was placed because the tool will take care of both the suction and liquefaction.

Conclusion

If you just started working on your PCBs, you should know that it’ll take you some time to get used to using the heating tool, as well as a desoldering pump. But, if you focus on avoiding the aforementioned mistakes, you can ensure that your PCB board look and functions flawlessly.

So, now that you’re aware of all the mistakes you’ll have to avoid making, you really shouldn’t waste any more of your free time. Instead, you should use that time for reading some useful guides and watching some tutorials that’ll help you understand the entire desoldering process better.